Table of contents:

Key Advantages of Stainless Steel Sintered Filter Cartridges in Industrial Applications

What Makes a Reliable Filter Cartridge Manufacturer in Today’s Market

How to Extend the Lifespan of Your Filter Elements

Key Advantages of Stainless Steel Sintered Filter Cartridges in Industrial Applications

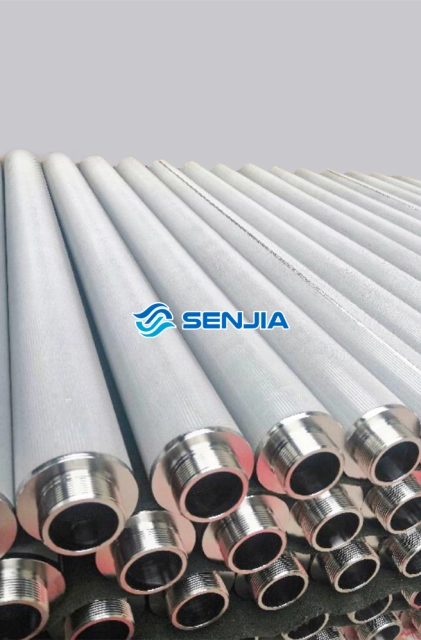

Stainless steel filter cartridges, particularly those made using sintered mesh technology, offer unmatched benefits across various industrial setups. The sintering process ensures a robust structure by stacking and vacuum sintering multiple layers of stainless steel wire mesh. This results in filter cartridges that are highly durable, resistant to corrosion, and capable of withstanding extreme temperatures ranging from -200°F to 1200°F, as indicated in Senjia Environmental Sci-Tech's product offerings. These cartridges exhibit a uniform filtration accuracy of 1 to 200 microns, making them highly effective for tasks such as filtering water, oil, gas, pharmaceuticals, and chemical products.Unlike conventional filters, stainless steel sintered cartridges from Filter Element Store are easy to clean and reuse, lowering long-term costs and supporting sustainable practices. Their durable construction is designed to withstand heavy use, significantly reducing wear and tear over time. This ensures reliable and consistent performance even in tough and demanding environments, such as extreme weather conditions, heavy-duty usage, or high-pressure scenarios. This makes them an ideal choice not only for everyday tasks like commuting or routine work but also for more challenging conditions that require durability and resilience.

What Makes a Reliable Filter Cartridge Manufacturer in Today’s Market

Choosing the right filter cartridge manufacturer is critical for ensuring the quality and reliability of your filtration systems. First, they prioritize high-quality materials, such as standard five-layer sintered mesh, which guarantees excellent mechanical strength and prolonged usage. Second, these manufacturers provide customizations to meet diverse industrial needs, including options like threaded and flange connections for easy integration into varying setups. Additionally, their production facilities are equipped with the latest technology to ensure precision and high-volume manufacturing. Beyond product quality, top manufacturers excel by providing exceptional customer support services. These include quick and accurate price quotes to streamline decision-making, user-friendly e-commerce platforms for convenient ordering, and responsive communication channels for technical support or reordering parts. They may also offer personalized assistance, such as dedicated account managers or live chat options, ensuring that customers’ needs are addressed efficiently and professionally at every stage.

How to Extend the Lifespan of Your Filter Elements

Ensuring the longevity of your stainless steel filter cartridges not only reduces replacement costs but also maintains the operational efficiency of your systems. To maximize the life of your filter elements, routine maintenance is essential. This includes regular cleaning processes such as backwashing, which helps clear debris and ensures consistent filtration performance. Employing compatible cleaning solutions to avoid damaging the material is crucial, as harsh cleaners can reduce the effectiveness of the filtration layers. Proper installation and alignment of the filter element during setup also play a critical role in mitigating wear and tear. Furthermore, monitoring filtration systems for signs of clogging or damage allows for early detection and timely intervention. By implementing such practices, you can significantly enhance the durability and performance of your stainless steel sintered filter cartridges, ensuring they last longer and operate more efficiently. Proper maintenance, regular cleaning, and adherence to recommended usage guidelines can help prevent clogging, reduce wear and tear, and maintain optimal filtration quality over time.

Proper maintenance and care are essential to maximize the efficiency and lifespan of stainless steel sintered filter cartridges. By adhering to regular cleaning schedules, inspecting for wear, and sourcing reliable replacement parts, you can ensure optimal performance and cost-effectiveness. Investing time and resources into these practices not only protects your equipment but also contributes to a smoother and more efficient operational workflow.

No comments:

Post a Comment